-40%

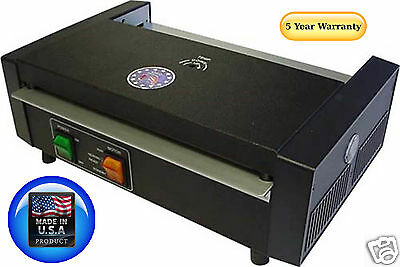

110V 63" Full-auto Take Up Large Format Hot & Cold Laminator Laminationg Machine

$ 1116.76

- Description

- Size Guide

Description

110V 60" Full-auto Take Up Large Format Hot & Cold Laminator Laminationg MachineStock in CA,USA!

Local pick up is okay, your shipping cost will be ZERO.

Kindly Note: Not Include the Air Compressor !!!

3 years warranty we guaranteed!

Lifetime Free Technical Support & Free Parts Replacement !

This is the enhanced and upgraded version compared our last laminator which can be used hot and cold laminating.

Multifunctional and high quality guaranteed!

Description:

This 60" high quality Full - auto Low Temp

Wide Format

cold laminator

with Stand can be widely used for pre - masking vinyl graphic, mount prints on substrate, over laminating inkjet prints and so on.

The cold laminator is used to after printing. Available for photographic, Ad. Shop and copy shop to do lamination work, adding a protective layer on books cover, photographic, color pages, documents, charts, drawings, indoor advertising products, etc.

This laminator 1600C6+ is

low heated cold laminator

with liner and without

liner, a wide range of application.

It can be used both cold laminating and hot laminating with low temperature, to strip coil backing paper,to roll picture

automatically.

Especially when work in hot laminating conditions,it will improve the

coating effect by heating the roller,.

It’s multiple-function,easy operation and high efficiency.

Model

SEC-010

Maximum Laminator Width

1520mm (60")

Roller’s Diameter

130mm (5")

Maximum Laminating Thickness

25mm (0.99")

Maximum Heating Temperature

when hot laminating, the temperature is 50~60 degree, the highest

temperature is 60 degree.

Laminating Speed

From

0 to 10m (393")

per minute

Preheating Time

5 - 10mins

Power Consumption

0.3 - 0.5KW / h

Power Input

2200W

Height Adjust

Single side lifting link

Motor Forward / Reverse

Yes

Floor Stand

Yes

Auto Rewind Liner Pickup

Yes

After Laminating Pickup

Yes

Emergency Stops

Yes

Safety Photocell

Yes

Power Supply

AC110V, 50 / 60Hz

This laminator comes with 2 pcs heating glass tube.

Features:

Adopts low temperature cold laminating, mainly used to solve the issue that cold laminated images are hazy.

Stainless steel feeding table

130mm (5") upper rubber roller

Auto – take – up system

Anti – tilt and anti – fold device (Origin)

Pressure and height adjust hand wheel

Infrared temperature control device

Details:

1. The emergency “stop”button

2. Machine leg

3. Cross brace 01

4. 40*60 Cross brace

Control Panel

using Instruction:

Preset temperature: Find out hot/cold framed switch, choose the "hot ", temperature display screen will light up, the left number is preset temperature, the right number is roller temperature, press “■ SET”key and then through “▲ UP” and“▼

DOWN” adjust preset temperature, after adjust it and press“■ SET”key confirm it. when cold film, the preset temperature is 50 ℃ .,the max temperature is 50 ℃.According to the viscosity of the glue, and adjust preset temperature.

Turn: This machine don’t have continuous reverse function;

In the "continuous" state it only can " turning";

In the "point move" state, through the pedal switch can "turning" or "reverse".

Governor knob: clockwise to grow speed, counter-clockwise to slow down; Please select the appropriate speed to ensure the laminating effect, when stop coated please select "point move".

General Using and installation method

Note:The hex nuts must be tighten! If loose will appear heating power electric spark change,and broken wire and other components.

Air Pressure Adjustment:

There is a Filter Voltage Stabilizer at the right back of the machine, as the picture;Pull the knob of the filter voltage stabilizer up softly, air pressure increases when rotating at clockwise direction. Air pressure decreases when rotating at the counterclockwise direction. Normal air pressure is 0.2Mpa.

3.The adjust of rubber covered roller ’s parallelism

Whether the parallelism adjusts well or badly,also can in fluent

effect quality and off tracking, the parallelism has been adjusted well when leaving the factory, but it still needs adjusting after using a long

time.

A-Pressure adjusting valve B-Pressure adjusting valve C-locking screw nut

1. When the parallelism gap of the rollers is slight, it can be adjusted by the following method:

a. Moving screw A to adjust the balance of the roller while it ’ s rising. Find out which side of the roller rises slower, then move the screw outward ( Or find out which side rises faster, then move the screw inward). Then raise and lower the roller until the roller is balanced.

b. Move screw B to adjust the balance of roller while it’ s falling. Find out which side of the roller falls slower, then move the screw outward ( Or find out which side falls faster, then move the screw inward). Then raise and lower the roller until the roller is balanced.

(Adjust the air pressure to 0.1MPa, the movement of the roller is slower than normal. It’s convenient to observe. )

Film laminating

Laminating work is an extremely fine, technical stronger work, for beginners should have experience in the technicians under guidance of Membranae tectoria work, the below only show the general operation.

Preheating ready to work:

1. Fall down tne upper nip roller;

2. Press the "continuous" and "turning" switch, governor rotate to the "1";

3. Open the main switch;

4. Open the "hot" switch and et the heat temperature which we required, then nip roller began to heating. Hot laminating, the preset temperature is 90 ℃ , when low temperature/cold laminating, the preset temperature set to 45 ℃ (to working temperature need about 10-20 minutes)

5. Take out a roll of film and install into material roller, then let roll into material feeding roller scaffold and pulling the film with the hand, shall ensure the appropriate resistance,through the next to the damping handwheel adjust it.

6. Let framed chart scroll in carton, then packed in rewinding stent and fixed them.

The general questions and methods

Problem

Control panel have no electricity

Method:

Check the power and emergency button

Problem

Don’t turn

Method:

Lift a little the upper roller

Adjust friction

Tighten sprocket key

Contact with motor or governor

Problem

Laminated paper isn't clear and have white point

Method:

Increase roller temperature

Clean the dust

Contact suppliers to replace film

Problem

laminated paper have pleated bubbles

Method:

Adjust roller force

Put paper in 90 angle into rubber roller

Increase speed and reduce temperature

Problem

Film fold

Method:

Adjust material-roller’s resistance

Adjust to the required temperature

Package:

Machine Dimension

74" x 27" x 45" (1880mm x 680mm x 1140mm)

Machine Weight

280lb (140kg)

Package

Fumigation free package

Packing Size

81" x 28" x 28" (2060mm x 710mm x 720mm)

Gross Weight

441lb (200kg)

SHIPPING

1.We will ship your item by FedEx, DHL, UPS, EMS, e-Package etc with the tracking number showed on ebay.

2.Your item will be shipped within 1-3 working days after clear payment .

3.The shipping time varies. If by FedEX, DHL,or UPS, 3-4 business days to USA,5-7 business days to other most countries.

If by e-packet,7-15 days to USA,and 2-4 weeks to other most countries.

4.Due to the local dispatch or other reasons, sometimes the shipping time will be delay. Please kindly understand Uncertainties by the delivery company.

5.

If you have not received your shipment within 30 days from payment, please contact us. We will track the shipment and get back to you in 24 hours.

Our goal is best customer satisfaction!

PAYMENTS

1. we accept: Paypal, Please contact us if you may need some other payment method.

2. We will very appreciate if you can pay for the order after your ordering within 1-3 working days so that we can provide you the best services.

3. Please list your special requests in message after payment. (color, packages, etc.)

4.S&H will be determined based upon your address. PLEASE NOTE: S&H DOES NOT INCLUDE DUTIES, LOCAL TAXES OR ANY OTHER IMPORT FEES.

Feedback

1.If you have any problems or concerns to your order or products, please message us and give us a chance to assist before you leave negative feedback.

2.We believe that we can produce a positive outcome to any situation to earn your like

s.

3.Your satisfaction is guaranteed.

Thanks for your business !